|

|

|

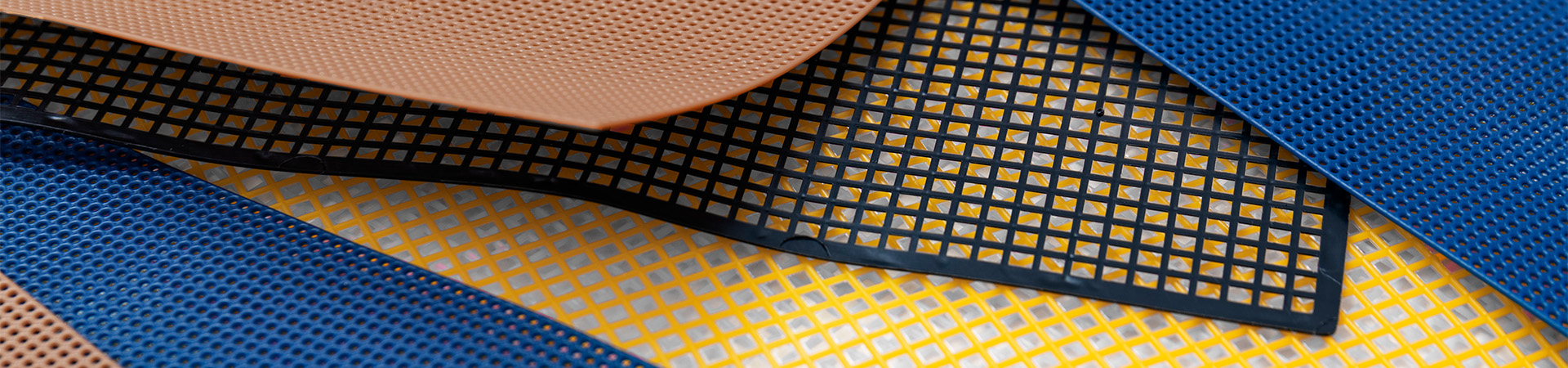

Pipes transport the materials that power machines, tools, and systems. Inside factories and large machines, pipes must move water, air, gas, or other liquids without trouble. But not every pipe can handle this task properly. Some pipes bend, leak, or break when the system becomes too hot or is under too much pressure. The GF Piping system resolves these issues. Choosing them isn’t just about picking a shape or colour. It means selecting the pipe that works best, lasts the longest, and fits perfectly in your system. This guide walks you through why GF Piping makes sense, what to consider before choosing them, and how they improve your industrial piping system. Importance of Selecting the Right Pipes in an Industrial Piping SystemAn industrial piping system, including the pipe and joint system, depends on every part doing its job. A single faulty pipe can slow down or block the entire operation. Pipes help systems run smoothly and efficiently, so picking the wrong one can damage everything. If your pipe can’t handle pressure or heat, it may crack or melt. That halts operations and wastes time. Choosing a strong GF Piping system keeps things moving. You also need secure GF pipe fittings to hold pipes in place. When you match pipe type, size, and components the right way, the whole system flows better and works longer. Key Factors to Consider When Choosing GF PipesBefore you select your GF Piping system, take time to think about what your system truly needs. These points help you decide with care: 1. Material TypeGF pipes are made from durable plastics like PVC-U, PP, and PE. These materials hold up well against heat, pressure, and chemical flow. Match the pipe to what it will carry and where it will run. 2. Pressure and Temperature RangeCheck if the pipe can handle high pressure or hot liquids. Look for pipes that perform well under stress. Use the pipe’s specifications to match its limits with your system. 3. Pipe Diameter and Wall ThicknessMake sure the pipe size fits your system’s needs. A pipe that’s too thin might snap, while a pipe that’s too thick might not connect well. Measure with care and match it with the flow you need. 4. Compatibility with FittingsUse GF pipe fittings that match the pipe’s size and material. Never force parts to connect. When parts fit together correctly, the system stays tight and safe. 5. Ease of InstallationChoose pipes that make setup quick and smooth. GF Piping connects easily and reduces mistakes. This means faster installation and fewer delays.

Benefits of Using GF Pipes in Industrial Applications1. DurabilityGF pipes resist rust, cracking, and damage from chemicals. This helps them survive harsh environments where other pipes may fail. 2. Precision FitGF pipe fittings grip tightly and hold their shape. This helps stop leaks and keeps the pipe steady during use. 3. Safe HandlingGF pipes are lightweight and easy to handle. Workers install them without heavy lifting, which keeps the setup simple and safe. 4. Low MaintenanceOnce in place, these pipes stay strong and clean. You won’t need to check or fix them often, which keeps your system working longer. 5. Cost EfficiencyEven though they’re strong, GF pipes don’t cost too much. They reduce repair costs and minimise downtime.

Need the Best Industrial Piping System?To keep your industrial piping system running properly, choose the pipe that works hardest without fail. GF Piping and GF pipe fittings give you long-lasting strength and a perfect fit. At Kyoto Automation Systems, we offer the best choices in high-quality piping. With our experience and full range of products, we help you pick what fits best. Choose Kyoto for smart piping solutions. We’ll help your system work right—every time. FAQsWhat are GF pipes made of?

Are GF pipe fittings compatible with other piping systems?

How do I select the correct GF pipe size and type?

Do GF pipes need special tools for installation?

|

|