|

|

|

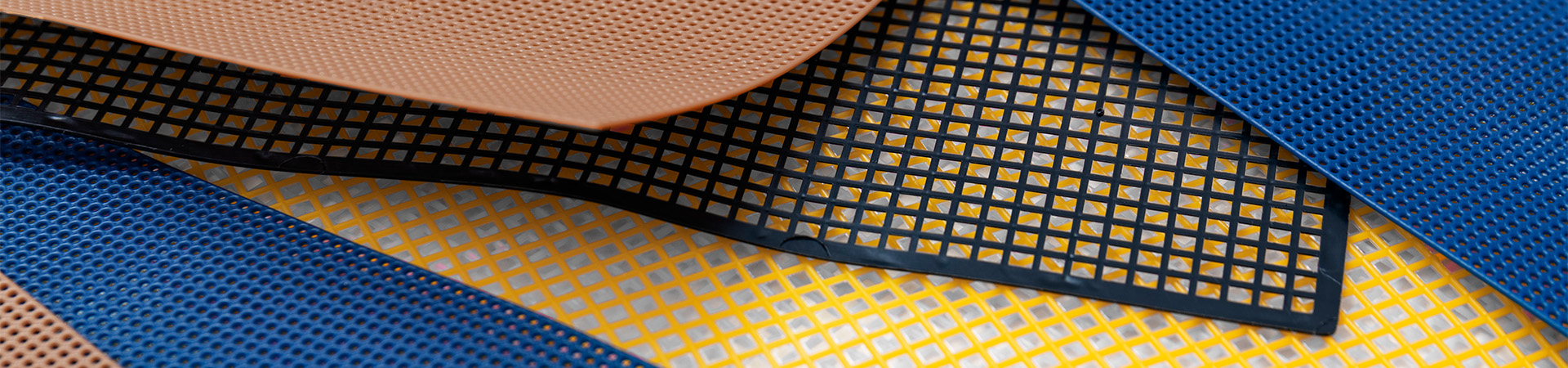

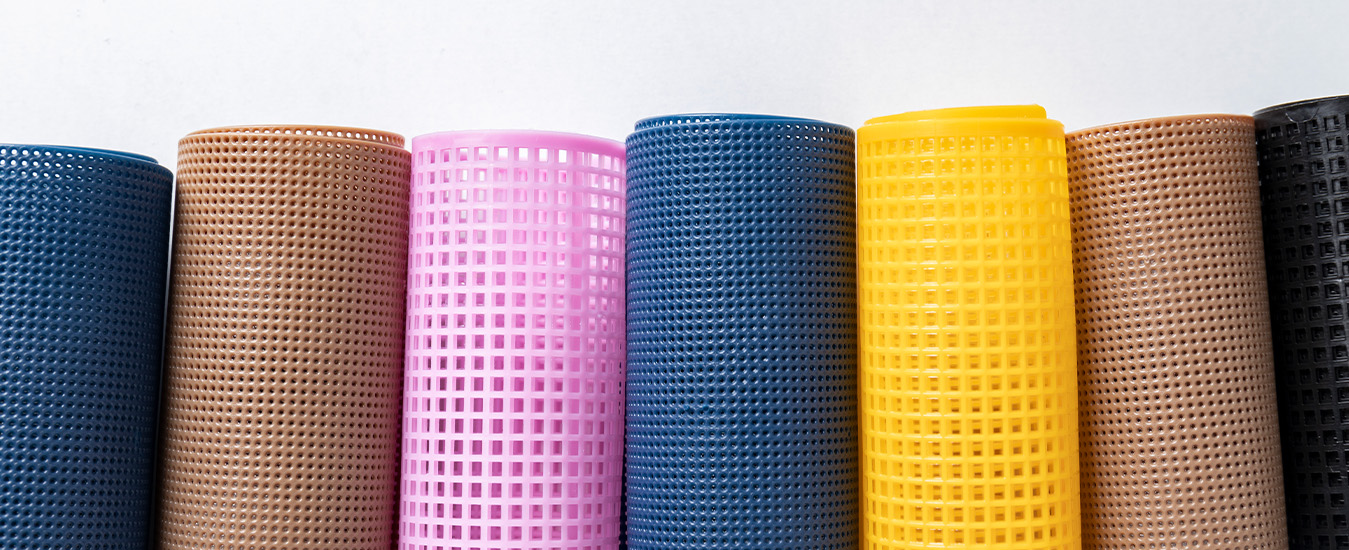

When working with delicate electronic components, safety goes beyond wearing gloves or using the correct tools. Invisible forces like static electricity can silently damage circuits, chips, and semiconductors. This is why many technicians rely on ESD mats for tables. These mats are more than just surface covers—they’re critical tools that guard against sudden electrical discharges. Understanding the role of electrostatic discharge (ESD) and how a simple mat can change the outcome of an entire production line helps prevent costly mistakes. This article walks through the essential benefits of using these mats during electronics assembly. Whether you are just setting up a workbench or reviewing your current safety protocols, this guide offers insights to support smarter, safer practices. Why Static is a Serious Risk in Electronics Assembly?In a normal setting, static builds up through friction—walking on a carpet, removing plastic packaging, or even rubbing sleeves against a chair. While this charge might be harmless to a person, it can be devastating to a printed circuit board (PCB). A sudden discharge may melt microscopic circuits, leaving devices damaged or useless. Manufacturing or assembling electronics without static control measures creates an unsafe environment for both the worker and the product. This is where electronics assembly safety protocols come into play, and among those, ESD control stands out as a core requirement. What Makes an ESD Mat Effective?An ESD mat for workbench setups often uses multiple layers to perform specific functions. One layer absorbs static, another safely conducts it away, and the final layer prevents the charge from reaching sensitive items. Some mats also include built-in ground points, which help carry the electrical charge to earth. These mats come in various types and materials. A popular choice includes a static dissipative mat, which slows down the flow of electricity and ensures that charges leave the surface gradually. This steady release reduces the chances of creating sudden electric surges. Key Benefits of ESD Mats for Tables1. Protects Electronic ComponentsThe most obvious benefit is component safety. Circuit boards, sensors, and microprocessors can all suffer damage from a small electrostatic charge. By placing them on ESD mats for tables, workers create a neutral environment. The mat acts like a silent shield, catching stray charges before they touch fragile electronics. This protection improves the yield of functioning devices, reduces repair costs, and limits returns due to faulty units. Over time, this leads to more reliable products and happier clients. 2. Creates a Grounded WorkspaceNot all surfaces are safe. Wooden benches, metal tables, and plastic sheets all carry different risks for static build-up. An ESD mat standardises the workspace, giving every technician a known, tested, and grounded surface to work on. When a mat connects to a common ground point, it ensures that both workers and tools remain at the same electrical potential. This prevents the sudden transfer of static energy from the hand to the component. It’s a simple but vital layer of control in any ESD-safe area. 3. Improves Assembly ConsistencyIn a busy production line, consistency matters. A static event might not damage every part, but even one failure in ten can disrupt delivery timelines and raise warranty claims. Using an ESD mat for workbench consistency means every item receives the same level of protection. It sets a baseline for quality and removes one variable from the equation. Staff can work with more confidence, knowing that the surface under their hands isn’t contributing to silent damage. 4. Supports Worker Safety and ConfidenceAlthough ESD threats primarily impact components, they also benefit workers. When staff know they’re handling high-value parts in a safe space, they worry less and focus more. The mat marks a clear boundary. Everything inside is controlled, tested, and grounded. This visual cue enhances discipline on the floor and helps train new workers more quickly. 5. Helps Meet Industry StandardsIn regions with strong manufacturing bases, such as those using ESD mat Malaysia standards, industry regulations often require ESD protection. Certification bodies such as ANSI and IEC establish safety standards for workplaces, particularly in aerospace, defence, and medical technology. Having the correct ESD mats already in place speeds up audits and ensures compliance. It also opens doors to clients who demand higher manufacturing controls. Choosing the Right Mat for Your TableESD mats vary significantly in quality. Factors such as material, thickness, layers, and resistance levels impact their performance. A static dissipative mat is ideal for general use, offering a balance between safety and comfort. Conductive mats are more effective in grounding charges, but may not be suitable for every bench or environment. Before buying or installing, always check:

Types of ESD Mats at a GlanceTo make selection easier, here’s a quick comparison of common ESD mat types: Each option offers distinct benefits. Review your workplace needs before choosing.

Maintenance MattersESD mats work best when maintained. Over time, dirt, oil, or flux residue can build up and interfere with conductivity. Using approved ESD-safe cleaning solutions for mats helps prevent issues and maintains high performance. Avoid using household cleaners. These substances can form a film on the mat that blocks static flow, which makes the mat less effective. Staff should follow a regular maintenance schedule and test mats for resistance at set intervals. Beyond ProtectionUsing ESD mats isn’t only about protecting parts. It sends a clear message to everyone in the room: this is a workspace where detail matters. Once workers see that static control tools are in place, they begin to adopt safer habits. Wrist straps get worn more often. Grounding points stay tested. Tools get stored in antistatic bins. The mat, though passive, acts as a trigger for better habits. This culture shift leads to fewer accidents, tighter process control, and fewer delays. It raises the standard not only of the products but of the entire workplace. Common Mistakes to AvoidEven with the right mats, problems can creep in. Here are some of the most frequent issues seen in electronics assembly setups:

Each mistake reduces the mat’s ability to protect equipment and people. Regular checks and proper training help avoid these pitfalls. ConclusionUsing ESD mats for tables brings more than just static protection—it brings confidence, consistency, and credibility to electronics assembly. These mats are silent workers, reducing invisible threats that could otherwise cost thousands in rework, repairs, or client dissatisfaction. To create safer, more reliable systems, teams should choose high-quality mats, keep them clean. Whether you're working on a basic ESD mat for workbench setup or operating under strict ESD table mat Malaysia standards, these tools act as unsung heroes. At the heart of every precise, safe electronics project lies attention to detail—and often, that detail begins at the table. |

|